Wastewater, also known as raw sewage include but is not limited to water from the bathroom, toilets kitchen and other industrial wastes.

Wastewater treatment is a process of removing micro-organisms, contaminants and any other pollutants from the wastewater.

Everyday wastewater from our homes, schools toilets, businesses and even factories goes down and flows into the City's sewer system.

Also the runoff from the rain, melting snow and street washing flows into the catch basins and then to the sewers.

Basically wastewater treatment is a simple process to convert the wastewater into the bilge water which can then be discharged back to the environment.

This wastewater is full of contaminants such as chemicals, bacteria and other toxins. The main reason for treating is to ensure that this water is treated into an acceptable level which is safe for discharge back to the environment.

Wastewater treatment process is also a process by which contaminants and other pollutants are removed from wastewater using well advanced equipment and methods.

As the word suggests, cleaning raw sewage is a process. It is done in stages up to the final stage where the water is released into the river.

Wastewater Treatment Process Step by Step

The following is a step by step process about wastewater treatment

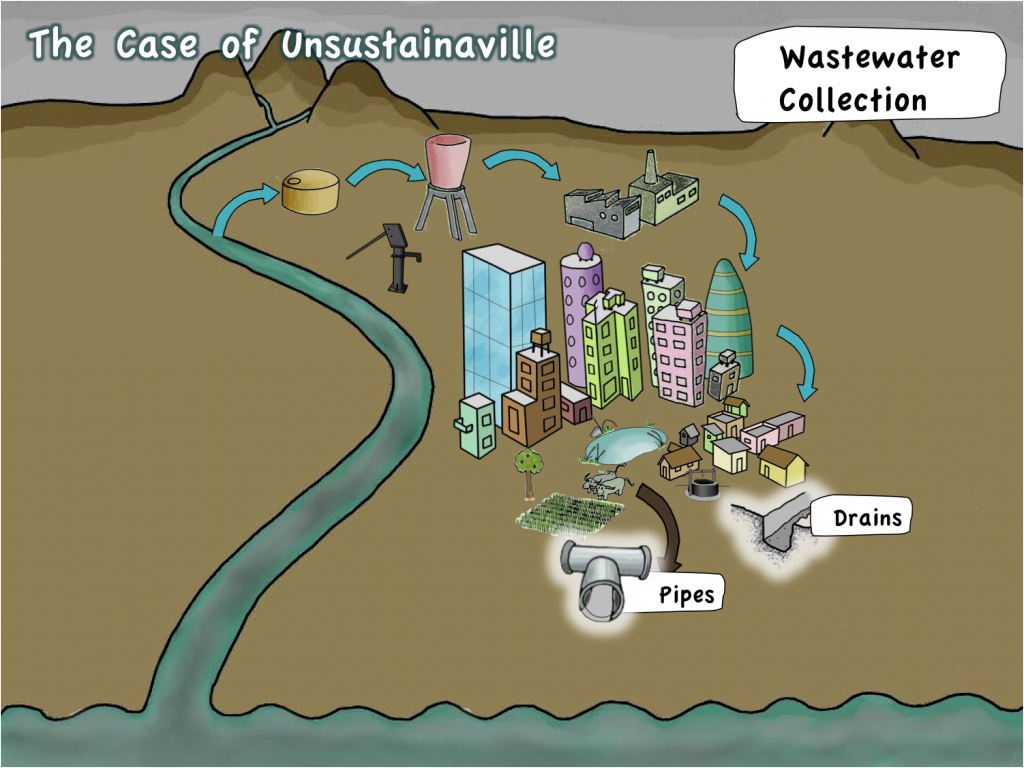

Step One : Wastewater collection

Wastewater collection is the first step in the process. The collection system is normally put in place by home owners, municipal administration as well as the business owners.

They ensure that wastewater is collected together and then directed into the central point.

This process is normally done in a structured way. The wastewater is directed using the underground drainage systems into the treatment plant.

Exhauster tracks which are normally owned by business people can also be used to direct this wastewater into the treatment plant.

The process of transporting this wastewater into the treatment plant should be done in hygienic conditions. It is important to ensure that the pipes or tracks do not leak and individuals offering these services should put on protective clothing.

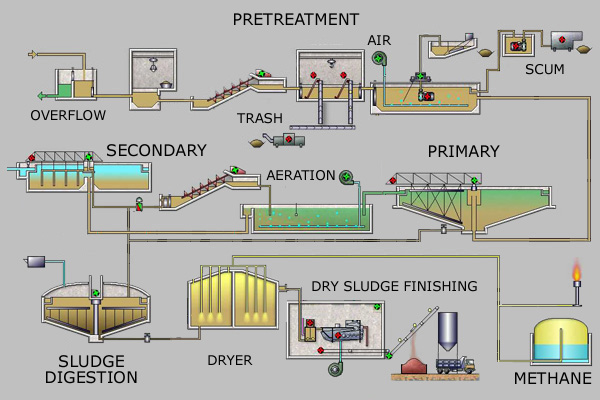

Pre-Treatment

This is the very second step in raw sewage treatment. It is meant to remove items such as broken bottles, wipes, sanitary items, diapers among others which may destroy the equipment during the process.

At this stage, grit and sand is removed too. It is a very basic process in Wastewater Treatment Plants (WWTP). After it is removed, it is then rinsed in the sewer.

Pre-treatment entails the screening and then removal of large particles or debris from raw sewage. This is because all these debris do not readily biodegradable through the bacteria process.

The debris are then dried up and then incinerated. Sand and grit are then settled out in the tanks as indicated above.

Odor Control

Wastewater contains many dirty substances that may cause foul smell after sometime. This smell is not pleasing to the environment and this is why odor control is very important.

To have a surrounding environment that is free of the odor smell, the odor treatment process shall be initiated. The process is mainly initiated at the treatment plant.

This is done by containing the wastewater and treating it with chemicals. This chemical will automatically neutralize the smell producing elements.

This is one of the most important process that you will not miss.

Screening

Screening is the next step in the wastewater treatment process. It involves removing all the large objects that may have remained after doing pre-treatment.

In this process, everything is almost the same as in the treatment process. The difference is that screening is more advanced. It involves the removal of all solid products.

This is the step that you will ensure that you don't forget. If you will fail to observe the step, your machines and equipment will develop mechanical problems because of the objects inside the wastewater that can easily damage them.

There are deigned equipment which are specially designed to perform all this functions of getting rid of unwanted product in the wastewater.

These solid wastes are then transported and disposed away after being removed from the wastewater. They are normally disposed off in the landfills.

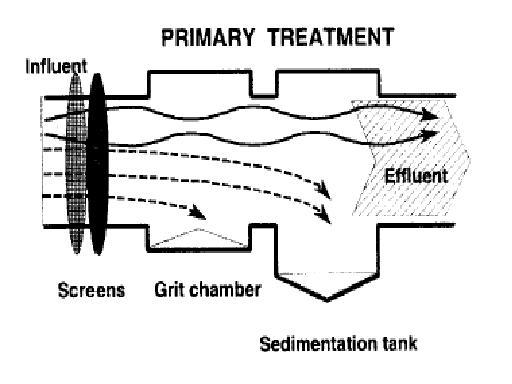

Step Two : Primary Sewage Treatment

This is another settlement stage which involves separation of solid macrobiotic matter from wastewater. The process is simply done by pouring wastewater into the big tanks so that the solid matter can settle on the surface of the tank.

At this stage, the water is classified into two. One is the organic matter, which is in solid form and the wastewater.(now without solids) this is done by putting it in a large tank that is called settlement tank.

Since the wastes are denser, they sink at the bottom of the tank. The wastes that sink at the bottom of this tank are known as sludge.

The wastes are then pushed to the center by large scrappers which continuously remove them from the bottom.

At the top, there is another layer of fats which floats since it is less dense than water. This layer of fats forms a crust.

The water between the crust and the sludge, which is now homogenous, is taken to for secondary treatment. This makes the treatment more proficient.

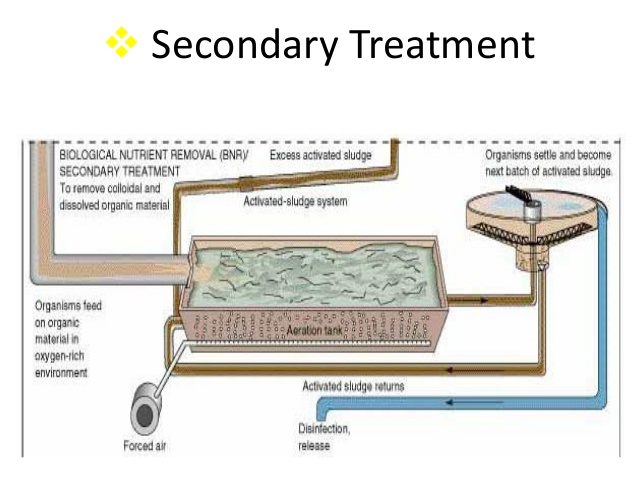

Step Three : Secondary Sewage Treatment

In this stage, Oxygen (O2) is introduced into the water. In simple terms organic compounds are broken down into a form that is easier to remove from the water. This helps break down the sludge that may have escaped in stage 2.

Secondary treatment is also known as activated sludge process. At this point, you will add seed sludge into the wastewater in order to break it down further.

First you start by pumping air into the huge aeration tanks that has a mix of wastewater with a seed sludge. A small amount is pumped in to fuel the growth of bacteria which basically use oxygen.

It also fuels the growth of microorganisms which consume all the remaining organic matter.

After a short while, you will experience the production of debris which will normally settle down at the bottom of the large tank. Water can pass through the huge tank in three to six hours

Humus and the dead bacteria settle out in another chamber for extra treatment.

Bio-solids handling

The final solid matter that settles down after primary and secondary treatment process, are then directed into the digesters. Digesters are then heated strongly at the room temperature.

These solid wastes are heated. They then undergo the process of anaerobic digestion.

At this stage, methane gas is produced and the formation of nutrient rich bio-solids is also experienced.

They are then recycled and then dewatered to the local firms. This methane gas that is formed is mostly used as the source of energy.

It is used in the treatment plant and can also produce some electricity in driving plant equipment. In the boilers, the gas is also necessary since it helps in generating some heat for digesters.

Step Four: Tertiary Treatment

Tertiary treatment is very important especially where the discharge points is very sensitive. These sensitive points include streams or dams where the water will be used directly by plants animals and people.

Tertiary treatment is very important especially where the discharge points is very sensitive. These sensitive points include streams or dams where the water will be used directly by plants animals and people.

This vital stage involves treatments such as

a.Chlorination

b.Ozone treatment

c.Use of Ultra Violet light to disinfect

d.Reducing the level of Nitrogen

At tertiary treatment stage all impurities are removed from the wastewater. This stage is almost similar to that used in the drinking water treatment plant. It ensures that 99 percent of impurities are removed.

At this stage wastewater is treated to an extent that it produces effluent water which has almost same quality as that of the drinking water.

The process is a bit more expensive because it requires special equipment, highly skilled and well trained equipment operators and strong chemicals together with a steady supply of energy.

Disinfection

After going through all the processes, you can still find some diseases causing organisms. To complete eliminate and remove all these organisms, wastewater is then disinfected for about 20-25 minutes inside those tanks that have the mixture of sodium hypochlorite and chlorine.

The process of disinfecting is an integral part in wastewater treatment process. This is because it protects the health of local people and animals who may use this water for other purposes.

Step Five : Sludge Treatment

The produced and collected sludge at the primary and secondary levels requires a high concentration and thickening process. This is achieved by putting them into the thickening tanks then let it to settle down and then separate it later from the water.

The process of sludge treatment may take up to 24 hours. After treating the sludge, the remaining water will then be collected and reversed back to the large aeration tank to enable further treatment.

After treatment of sludge, it is then sent back to the environment for agricultural use.

From this point, the water is safe for use and is therefore released into the river.

Conclusion

Wastewater treatment process is seen as a very complex, expensive process. While this is not fully undeniable, the process is very important and is worth the cost. WWTP are very effective especially when they have designed with expertise. With very little maintenance, the plant will serve for a lifetime.

Pages you might like

Pages you might like

Latest information

Latest information

Follow official account

Follow official account

Online support

Online support

鄂ICP备2022017323号

鄂ICP备2022017323号

鄂公网安备 42018502006493

鄂公网安备 42018502006493

Launch Exhibition

Launch Exhibition

Release information

Release information

Today's topic

Today's topic